Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

Optical Rigid Endoscopes:Transmit images through lens assemblies, suitable for straight-channel inspections (e.g., direct cylinder inspection in engines).

Fiber Optic Endoscopes:Use fiber bundles to transmit images, ideal for small apertures and complex internal structures (e.g., transmission systems).

Electronic Video Endoscopes:Employ CCD sensors for high-definition imaging and digital processing (e.g., resolutions above 440,000 pixels).

Key Technical Parameters

Probe Diameter:Ranges from 2.8 mm to 8.5 mm (e.g., a 4.5 mm probe for new energy battery pack inspections).

Focus and Field of View:Supports variable focus (macro to infinity) with a 120° viewing angle for broad inspection coverage.

Illumination System:LED cold light source with adaptive brightness adjustment to minimize metal reflection interference.

Special Features:IP67 waterproof rating, motorized focus, axial rotation (e.g., 360° omnidirectional observation).

Engine Inspection

Inspection Targets:

Cylinder walls, piston rings, and valves for wear, cracks, and carbon deposits.

Verification of oil and water passage flow (e.g., detection of cylinder casting defects).

Case Study:An automotive manufacturer identified early wear in engine combustion chambers using an endoscope, preventing a large-scale recall.

Transmission Inspection

Inspection Targets:

Gears and bearings for wear or foreign object intrusion (e.g., metal debris).

Clutch plates and synchronizer surface quality verification.

Advantage:Enables direct observation of internal mechanical conditions without dismantling the transmission.

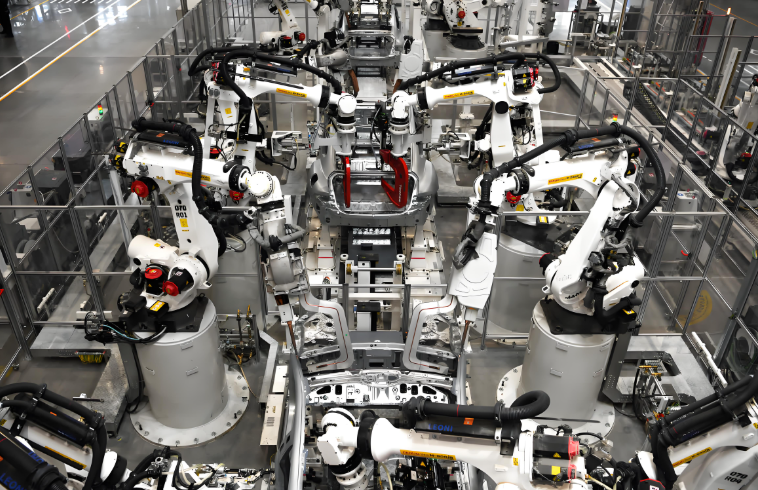

Welding Quality Inspection

Inspection Targets:

Weld joints on the car body (A/B pillars, doors) for seam integrity, penetration depth, and cracks.

Internal cavity coating, wax application quality, and filler uniformity.

Case Study:A specialized inspection institute generated a pressure vessel inspection report within 30 minutes using endoscopes, meeting TSG 21-2016 standards.

Other Applications

Brake Systems:Detection of internal corrosion or blockages in pipelines.

New Energy Battery Packs:AI-assisted identification of welding defects reduced missed detection rates from 0.3% to 0.05% in a new energy vehicle factory.

Non-Destructive Testing:No need to disassemble components, reducing downtime and costs.

High-Definition Imaging and Measurement:Supports 3D stereoscopic measurement (e.g., single-lens phase scanning technology) for precise defect sizing.

Intelligent Upgrades:Integration of AI defect recognition and MES system connectivity enhances inspection efficiency.

Industry Trends

Miniaturization and Portability:Probe diameters are shrinking further (e.g., 2.8 mm) to access tighter spaces.

Function Integration:Combines ultraviolet inspection (penetrant testing) and robotic crawlers (e.g., wind turbine blade inspections).

Intelligent Systems:AI-assisted analysis, automatic report generation, and cloud-based data storage are becoming standard features.

Industrial endoscopes play a critical role in the automotive manufacturing industry, supporting non-destructive inspection, high-definition imaging, and intelligent analysis in engines, transmissions, welding, and other key processes. Ongoing technological advancements, including miniaturization and AI integration, are further enhancing quality control efficiency, making industrial endoscopes an indispensable tool for modern automotive production.

Industrial borescope

solution service provider