Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

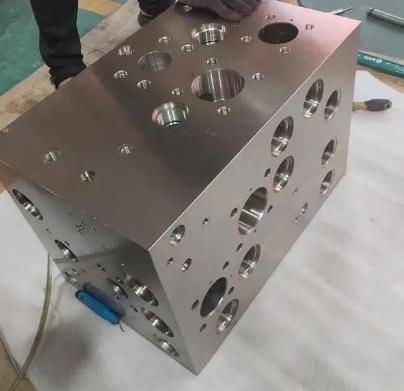

Equipped with a high-definition camera, it can clearly display the internal details of the valve block. In hydraulic valve block inspection, it can detect tiny burrs, cracks, corrosion, and other defects that are often difficult to find with traditional inspection methods. For example, in the production of automotive hydraulic valve blocks, burrs are one of the main defects. If not dealt with promptly, they can lead to a decrease in valve block performance, or even detach during machine operation, forming solid metal particles that enter the hydraulic system, contaminating the hydraulic oil, blocking valves and pipelines, and causing hydraulic system components to fail, its high-precision imaging capabilities allow inspectors to promptly detect and address these minute defects, thereby avoiding potential safety hazards.

1.Flexible Inspection, Adaptable to Complex Structures

The internal structure of valve blocks is complex, containing numerous channels, bores, and valve components. Zhenben Industrial endoscopes feature a flexible probe design that can penetrate narrow spaces for comprehensive inspection. Its insertion tube can be bent into various shapes, adapting to different inspection angles. For example, in the inspection of ship engine cylinder block pipelines, the small lens diameter of the Zhenben Industrial endoscope allows it to easily enter narrow pipelines, enabling comprehensive inspection without blind spots. This flexibility allows Zhenben Industrial endoscopes to cover more areas in valve block inspection, reducing blind spots and improving the comprehensiveness and accuracy of the inspection.

2. Strong environmental adaptability ensures stable operation.

Valve blocks may be exposed to various harsh environments, such as high temperature, high pressure, and corrosive conditions. Zhenben industrial endoscopes feature waterproof, dustproof, and high-temperature resistance characteristics, enabling them to operate normally in these harsh environments. For example, in power plants, the inside of boiler tubes experiences high temperatures and harsh conditions. Zhenben industrial endoscopes can withstand high temperatures and inspect the inside of boiler tubes, detecting potential problems such as creep cracks. This allows maintenance personnel to replace pipe sections in advance, preventing pipe rupture accidents and ensuring power generation safety.

3.Multifunctional integration enhances inspection efficiency

In addition to high-definition imaging and flexible inspection capabilities, it integrates various functions such as real-time image transmission, recording, and measurement. These functions enable inspectors to perform inspection work more efficiently. For example, in hydraulic valve block inspection, images can be transmitted in real time to a remote monitoring center, allowing experts to remotely view the images and provide diagnosis and guidance, improving the efficiency and accuracy of decision-making. At the same time, it also features measurement capabilities, allowing for precise quantification of defect sizes within the valve block, providing repair personnel with more accurate repair information.

4.Reduced maintenance costs and extended service life

Potential problems within the valve block can be detected in a timely manner, allowing for appropriate maintenance measures to be taken. This helps prevent serious damage to the valve block caused by long-term operation, thereby reducing maintenance costs. Regular inspections also extend the service life of the valve block and improve equipment reliability and performance. For example, during the use of automotive hydraulic valve blocks, regular inspections using industrial endoscopes can detect and address internal issues such as burrs, rust, and impurities in the channels, ensuring the normal operation of the automotive hydraulic system.

Industrial borescope

solution service provider