Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

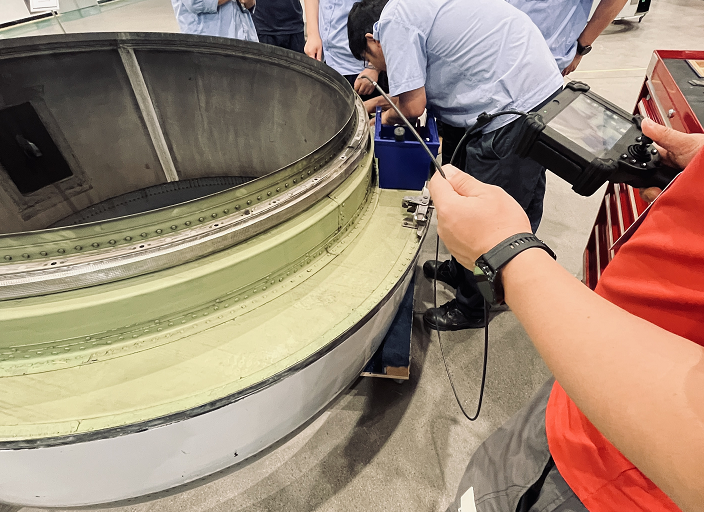

With its advanced technology and excellent performance, the VSNDT P series industrial endoscope has played an important role in the inspection of aircraft air intake covers by a Guangzhou aircraft maintenance engineering company, providing efficient and accurate inspection solutions for the aviation maintenance field.

High-precision imaging: The Microvision Optoelectronics P series industrial endoscope is equipped with high-definition imaging function, which can provide high-resolution video and images, ensuring that inspectors can clearly observe every detail inside the aircraft air intake cover and promptly discover potential problems such as cracks, wear, and corrosion.

360-degree rotating guide lens: The lens of this endoscope has a 360-degree rotating guide function, and inspectors can easily adjust the viewing angle to obtain a suitable viewing angle, especially when operating in a confined space. This function greatly improves the flexibility and convenience of detection.

Diversified pipe selection: The P series industrial endoscope provides a variety of pipe options such as tungsten braided hose, shaped tube, spring tube and alloy hard rod to meet the needs of different operating environments. When inspecting the aircraft air intake cover, the most suitable pipe can be selected for inspection according to the internal structure and space limitations of the air intake cover.

Strong durability: Made of high-quality materials, it has excellent corrosion resistance and wear resistance, and can operate stably in various harsh industrial environments. This is crucial for endoscopes that need to be used in aircraft maintenance environments for a long time.

Improve detection efficiency: The use of Microvision Optoelectronics P series industrial endoscopes enables a Guangzhou aircraft maintenance engineering company to quickly and accurately complete the detection task when inspecting aircraft air intake covers. Compared with traditional detection methods, endoscope detection does not require the removal of the air intake cover, which greatly saves detection time and cost.

Improve detection accuracy: The combination of high-definition imaging and 360-degree rotating guide lens enables inspectors to observe the internal conditions of the air intake cover comprehensively and carefully, effectively avoiding missed detection and false detection.

Support data storage and analysis: P series industrial endoscopes usually have data storage function, and inspectors can save images and video data during the inspection process for subsequent analysis and report generation. This is especially important in the field of aviation maintenance, because detailed inspection records are an important basis for aircraft maintenance and repair.

A Guangzhou aircraft maintenance engineering company highly praised the use of the Microvision Optoelectronics P series industrial endoscope. They said that this endoscope not only improved the detection efficiency and accuracy, but also reduced the detection cost and risk. At the same time, they were very satisfied with the professional after-sales service provided by Microvision Optoelectronics.

Industrial borescope

solution service provider