Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

The higher the pixel of an industrial endoscope, the better. Instead, it needs to be weighed comprehensively according to the specific application scenario, detection requirements and cost budget. The following analysis is carried out from three dimensions: technical principle, application scenario and cost-effectiveness:

The core role of pixels

Pixels are the basis of image resolution and determine the ability to capture details of the image. For example:

A 5-megapixel endoscope can clearly present tiny cracks (such as 0.01mm level) and can accurately identify early damage in the inspection of aircraft engine blades.

A 2-megapixel 1080P endoscope is suitable for large-diameter inspection (such as pipes above 6mm), which can clearly show internal corrosion or weld defects.

Limitations of pixels

Too much is as bad as too little: In narrow spaces (such as 0.1mm tiny pipes), too high pixels may cause image overload, which in turn reduces observation efficiency.

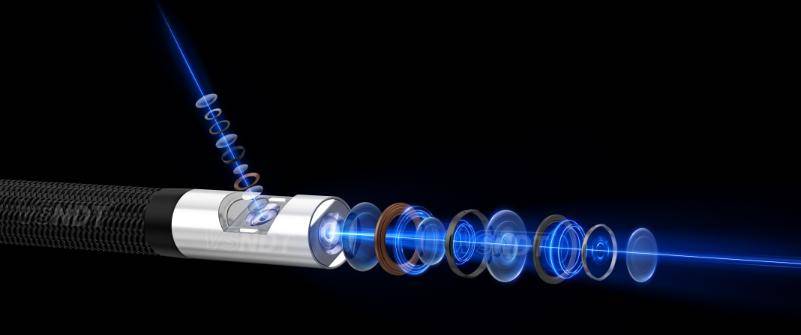

System synergy: Image quality also depends on the sensor type (CMOS/CCD), lens optical quality, light source intensity and image processing algorithm (such as automatic white balance, noise reduction). For example, although the pixel of a certain brand of endoscope is not high, it can still maintain high definition in a dark environment through AI image enhancement technology.

Application scenarios Typical pipe diameter/space Recommended pixel range Core requirements

Precision parts inspection 0.1-0.9mm tiny pipes 10,000-160,000 pixels Balance field of view and details to avoid image overload

Medium diameter equipment inspection 0.9-2.8mm pipes 160,000-300,000 pixels Clearly present defects such as cracks and pitting

Large cavity/complex structure inspection 2.8-6mm pipes 1 million pixels (720P) High-definition imaging, support for three-dimensional measurement

Extreme environment inspection 6-8.3mm pipes 2 million pixels (1080P) Ultra-high definition, capture tiny defects

The hidden cost of high pixels

Equipment cost: The price of a 5-megapixel endoscope may be 3-5 times that of a 10,000-pixel device.

Maintenance cost: High-pixel sensors have higher environmental requirements (such as dust and shock resistance), and maintenance costs may increase.

Operation efficiency: Too high pixels lead to large image files, which may slow down data processing.

Cost-effective optimization plan

Small and medium-sized enterprises: Choose 160,000-300,000 pixel devices, taking into account clarity and cost (such as a certain brand of 160,000 pixel endoscope, which is moderately priced and supports video recording and data transmission).

High-end demand: In the fields of aviation and energy, 2 million pixel devices combined with three-dimensional measurement technology can achieve accurate quantitative analysis of defects.

Positive feedback

Performance in dark light environment: A 5 million pixel endoscope clearly captures gear pitting defects through automatic light intensity adjustment in wind power gearbox inspection.

Convenience of operation: Endoscopes that support Wi-Fi transmission can transmit images to mobile phones in real time, improving on-site inspection efficiency.

Potential shortcomings

Anti-fall: Some high-pixel endoscopes need to be equipped with protective covers in rough industrial environments.

Extreme environment adaptability: Special models should be selected for high temperature or corrosive scenes (such as a certain brand of IP68 protection level endoscope).

Conclusion: Pixel selection needs to be "adapted to local conditions"

The pixel selection of industrial endoscopes should follow the following principles:

Scene priority: Determine the pixel range according to the size of the inspection object and the complexity of the environment.

System matching: Ensure that components such as sensors, lenses, and light sources work together.

Cost controllable: Avoid paying a premium for redundant performance and choose the most cost-effective solution.

For example, when inspecting automobile engine cylinders, a 1 million pixel device is sufficient to meet the needs; in the inspection of aircraft engine turbine blades, a 2 million pixel device combined with AI-assisted analysis can achieve efficient and accurate defect recognition

Industrial borescope

solution service provider